How To Install Cooker Hood Extractor

Ventilation Ducting for Kitchens – How to Install a Cooker Hood to Reduce Steam and Condensation in the Kitchen

In this project nosotros become through the steps involved in installing a cooker hood above your cooker. Learn how to mountain the hood on the wall including and associated ducting , drill a hole through an external wall then that any extracted air can be vented externally and also how to wire up the cooker hood and what rules and regulation you demand to be aware of.

Your bathroom and kitchen is a rather unique place. No other rooms in your domicile are subjected to the huge variations in temperature or moisture levels in the air than these two spaces.

You may be thinking; why does it matter that they get hot or cold and a fleck steamy? Well, when it comes to ensuring that black mould is non allowed to form or condensation is prevented from causing a whole host of bug so this matters a not bad deal.

The only way to manage the volumes of water vapour and wet in the air in both of these spaces is through the utilize of ventilation and extraction, to remove it and ensure that the air that's replacing it is clean and fresh.

Pan on a hob producing lots of steam and water vapour

This process can be as uncomplicated as opening a window, but generally involves the installation of an extractor fan or cooker hood and extractor with any associated ducting.

To these ends, we will run through what's involved in ensuring that the air within your domicile is as fresh and clean as possible and how y'all can easily and cost effectively reach this.

It's also worthy to note that Kitchen and bathroom ventilation is at present an important greenish issue.

Why practice you Need Ventilation in Kitchens and Bathrooms?

As we have briefly mentioned above, kitchens and bathrooms can be humid places. A pan boiling on summit of a cooker can chuck out a huge amount of steam and water vapour every bit can kettles and also other cooking activities.

With all of the activities mentioned higher up, estrus is also a key player. With cooking you lot are dealing with boiling h2o and pretty much the aforementioned with baths and showers, although the water is non quite as hot equally the water you will exist cooking with.

During whatever of these activities, any heat that is given off will chop-chop start to heat the room or space that you are in, plus too requite off lots of steam and water vapour.

The chances are that none of the walls in your room will be at the same temperatures and in pretty much all instances, will be a fair flake colder. When hot, boiling air meets a common cold surface, the h2o within that air condenses onto the surface. This is commonly known every bit condensation.

Lots of condensation collecting on a window pane

The life style of washing and cooking for an boilerplate couple living in a standard sized house will produce nigh four litres of moist air per day, that'due south quite a bit wouldn't you say.

If this process is allowed to repeat over again and again with very little or no ventilation or extraction, over fourth dimension it can lead to issues with blackness mould than can in turn impairment plaster, painted surfaces, timber and, more chiefly, also harmful to your health!

With this in mind, I'thou certain you can capeesh that it is of loftier importance to control and limit the volume of humidity in a room space and also reduce the possibility of any class of mould forming.

In previous years, natural draughts and ventilation within a property would have taken care of much of this moist air but in the drive to retain rut in the home through cavity insulation, double glazing etc to exist much more environmentally friendly and free energy efficient, this moist air can go trapped.

If you would like to notice out more most condensation and it'due south causes and cures, see our project here.

Ventilation and Extraction in Kitchens

Firstly an obvious one – open some windows. Although maybe a picayune obvious, sometimes this isn't always practical. If it's in the dead of winter and freezing cold outside, the last thing you lot might desire to do is open your windows and let any precious estrus out.

Bated form this, if it's non winter, so an open up window tin go a off-white mode to letting out unwanted steam and humid air, and so if yous can, do it.

Side by side, and in all honesty probably the all-time and most common route is to install a cooker hood.

These are quite common place in nigh homes these days, just if you take never seen 1 or used one, essentially it'south a adequately large hood that is fixed to the wall above your rings or hobs that has a suitable size extractor fan build into it.

A cooker hood in place above a gas hob

When the fan is switched on, is sucks all the steam generated past any items cooking or boiling beneath upwardly, upward through ane or more ducts or sections of pipework to a place where information technology can be vented externally. About of the time this will be a vent in your wall or soffit.

In most cases, installing a hood can block a lot of lite from your rings or hobs, making it difficult to come across whatsoever is on them. Fortunately cookers hoods also feature a handy in-built calorie-free that can be turned on so that you tin see what your doing and how your cooking is progressing.

There are quite a few unlike types on cooker hood bachelor on the market place today, simply this is in essence how pretty much all of them operate.

Installing a Cooker Hood

In terms of the complexity of this job, if you lot have a good grounded cognition of DIY and basic electrics so this should exist no problem at all. If not, then we would strongly advise that you get the professionals in.

If y'all do feel that you are capable, read on.

What to Call back of Earlier Installing a Cooker Hood

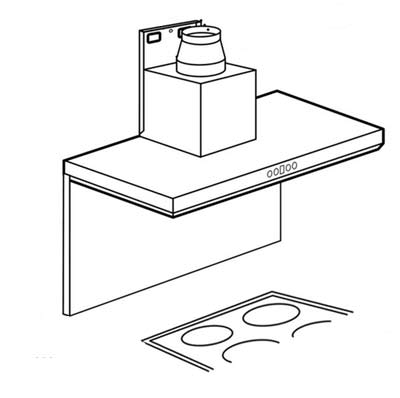

The type of cooker hood that you have will dictate how it is fixed to the wall and also where any ducting will need to run to get to an external wall in social club to vent externally.

For the purposes of this tutorial, nosotros are going to be installing an externally venting chimney cooker hood. These are a adequately common selection when it comes to installing hoods later on the initial installation of a cooker.

With this type of hood we are going to need a way to vent it externally. This substantially means making a fairly large hole in a wall.

In order to do this, we firstly demand to check the exterior wall of the holding to make sure in that location is noting that's going to get in the fashion of where nosotros need to make our external vent.

For example, gas mains sometimes run up and forth external walls so if something like this is in the way, information technology will need to be moved by a GasSafe registered Gas Engineer.

Similarly, y'all will need to run over the internal wall expanse where the hood is to exist fitted with a cable, piping and stud detector to make sure that at that place are no pipes or wires buried in the wall that could easily be drilled into.

For help with using a stud detector, run into our project here.

What Dissimilar Types of Cooker Hood are There?

In respect to the different types of cooker hood, at that place are a few. Merely then that you are enlightened, they are as follows:

- Integrated – Built and designed to fit perfectly with integrated kitchens and units. Commonly subconscious and a door or flap needs to be pulled out and then that information technology can be used

Integrated cooker hood – Image courtesy of stovesrus.co.great britain

- Ceiling Mounted – Ordinarily used for island cookers (cookers located in an island in the centre of a kitchen), these are either flush-mounted in the ceiling or dropped downward in a housing to get more than of a feature

Ceiling mounted cooker hood – Epitome courtesy of extractair.co.u.k.

- Designer – Generally for more modern and contemporary kitchens, they are built to form a feature within the kitchen

Designer cooker hood – Epitome courtesy of arredatutto.com

- Conventional – Standard cooker hood, normally fitted within a wall unit of measurement so that they continue a run of units, they are not hidden and are fully visible

Standard cooker hood – Epitome courtesy of tlc-direct.co.uk

Each of the variations to a higher place, including our chimney hood, will either exist an air extraction or air recirculation blazon.

As the proper noun suggests, the air extraction version will excerpt all the steam, cooking smells etc to the outside of your belongings, whereas the recirculation type volition make clean the steamy vapour through a series of grease and charcoal filters and then re-distribute the warm air back into your kitchen.

Both have advantages and disadvantages, the master ones being that pumping warm air that tin be used to heat your kitchen exterior is a terrible waste matter, merely too, pumping warm air around a kitchen in the tiptop of summer tin brand for an uneasy space to work in.

There's no right or incorrect solution, it'due south really up to you.

Annotation: One point to annotation though is that you will be unable to utilize a recirculating hood if you have whatever gas appliances in your kitchen. If y'all do then you lot volition demand to use an extraction hood.

As a few final endmost notes on the types of hood, when choosing your a hood, always look at the Eu Energy label and go for the almost efficient model you can. Ideally noting less than an A+ version.

The newer hoods should also feature an LED light over the older type halogen. LED's are mostly a much brighter and more than efficient option to go for.

One of the major bugbears with cooker hoods is the noise, so pay attending to the levels of racket each produces. Tis will be measure in dB (decibels). Something around 60dB will be fairly quiet.

An equivalent to this level of noise will be something similar general chat or background music in a eating house.

What Heights tin my Cooker Hood be Fixed at?

Moving dorsum to installing our hood, firstly we need to mark on the wall that the hood will be fixed to, the height that it needs to be stock-still at.

When it comes to cooker hoods, the rules for installation heights are equally follows:

- Minimum of 550mm for the hood above an electric cooker

- Minimum of 650mm for the hood above a gas cooker

- Maximum of 800mm for the height of the hood above both gas and electric cookers

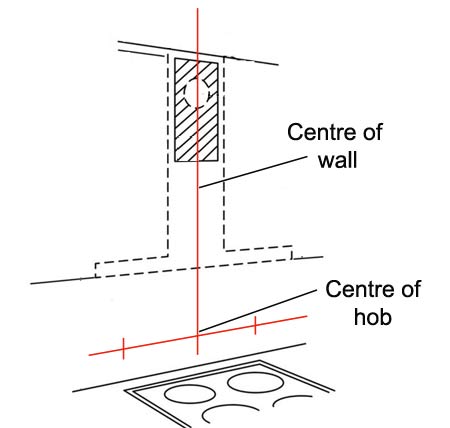

Measure and Mark Centre Points on the Wall

With the above rules in listen, work out how high your hood is going to be above your rings or hob. This may be dictated to you lot by the superlative of your ceiling and the pinnacle of the actual chimney section of the hood in that the chimney section might reach all the manner upwards to fit flush with the ceiling at the correct superlative of between 600mm and 800mm from the hob itself.

Chimney type cooker hood fitted flush to the ceiling

Mensurate and mark a point on the wall either side of cooker with a pencil at the correct height that yous want your hood to be positioned at.

In nigh cases you volition be measuring up off of your worktop. This should exist level but it'due south best to check. Using a spirit level, place this horizontally on the marks that you made on the wall and check that all is level.

If not, elevator one end of the level until it is and remark the wall so that you now accept ii level points. Draw a pencil line between these ii points so that yous at present have a level reference betoken for your hood.

Next we need to ensure that your hood will be key to your actual hob/cooker beneath. Measure the width of your cooker and carve up this number by 2.

Now, position your tape measure at the rear left side of your cooker/hob and mensurate to the correct the number you arrived at higher up and mark this point on your wall.

Position a spirit level vertically correct on this marker and level up the level, using the pencil marking as the middle of vertical alignment (make sure the level is long enough to get all the way up to your horizontal line that marks the height of your hood).

When the spirit level itself is level, draw a vertical line across your horizontal line. This point at present marks the horizontal and vertical middle for your hood.

Finally, measure the width of your hood, divide this number by two so mensurate and make a modest marking of this distance on the rear of your hood and so that you can see it. This will marking the centre of your hood that you can utilize to marshal with the marks yous now have on your wall.

Centre of the hob marked on wall and center line marked up the wall

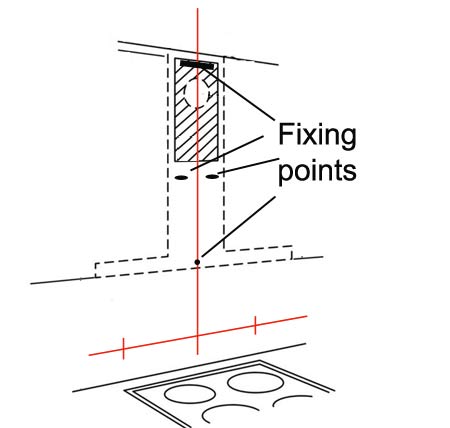

Measure and Marking Fixing Points for Hood and Ducting

When information technology comes to really fixing the hood in place, each manufacturer will take their own method or specially designed fixings or brackets, so brand sure you refer to your user manual for details on what fixing should be used where, simply generally, the principles of installing each volition be the same.

Most hood kits will come with a set of instructions that show all the dimensions of the fixing points on a given surface.

Unfortunately, without knowing where the points on the instructions relate to with your own wall, in virtually cases they are pretty much useless, so generally it'due south ameliorate to get it on the wall and so that you lot can marker the fixings yourself.

In this case, we are installing a hood that has the showtime section of ducting integrated on meridian of information technology. The hood itself is screwed to the wall and the ducting above it is hung on some brackets.

The last section of ducting then sits over the integrated ducting to hide the external vent position and is itself, secured to the wall past mounting brackets.

It'due south a good thought to get some help from a second pair of easily at this stage. The hood and ducting was lifted up into place making sure that the centre line of the hood is positioned at your vertical heart line marker on the wall and that it is also horizontally level with the level line marked on the wall.

Inquire your second pair of hands to hold the hood firmly in place, ensuring that it doesn't motion, while you use a pencil to marking a point on your wall for each of the fixings for the hood and ducting.

With the fixing points at present marked, remove the hood and duct and put it safely to one side.

Fixing points marked on wall gear up for drilling

Drill out all Fixing Points

With all of your fixings now marked on the wall, it'south time to drill them all out.

If you lot have manufacturer-specific fittings and then they should state in the instructions the size of pigsty that you volition need to drill. In nearly cases, this will be somewhere between 6mm and 8mm.

If you are drilling into solid masonry, you volition demand to utilise a masonry drill chip and a suitable sized drill or combi drill/driver (more tin be found near drills and drivers in our project here).

If you are fixing into a plaster boarded stud wall then you will need to use suitable fixings. More tin can be found well-nigh plasterboard fixings in our project here.

In this instance nosotros are fixing into a masonry wall and the manufacturer states to utilise an 8mm masonry bit for the size of wall plugs supplied.

Insert the drill bit into the drill and then drill out each of the holes. Make certain you run the drill in and out a few times once the hole has been drilled to clean out any dust and droppings.

With the holes drilled, insert your wall plugs co-ordinate to your instructions.

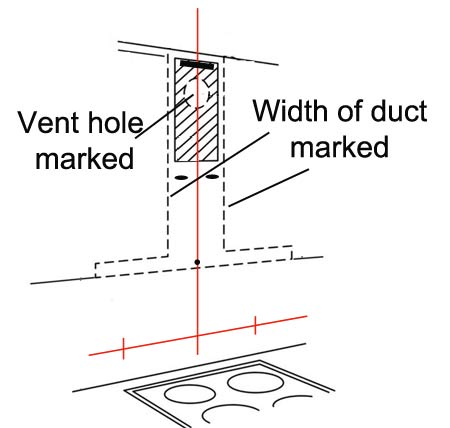

Examination Fit and Mark Position of Vent Hole

To insure that the any vent holes are fabricated in the right place, it's a very good idea to test the hood and ducting and so that yous tin then accurately mark where you are going to need to make your vent hole.

With some additional help, get the hood and duct upwards and lightly prepare it in place. Once there you can and then see where the top of duct exits the hood and class there, where you will need to run the additional ducting from that point, to the point where it will exist vented externally.

In terms of actually getting the air outside, you may have a few choices:

- Through the Wall: In almost cases, this is going to exist the way to go. A large hole is drilled through the wall and ducting connects to a vent on the outside wall

- Over the Wall and out the Soffit: Particularly good with bungalows or backdrop with deep soffits and hoods that run up to the ceiling. Ducting runs from the hood, through the ceiling and into the loft infinite and and then over the acme of the wall plate and down out through the soffit

Both of the above methods are suitable to use. If you tin can go up through the ceiling and then out through the soffit, this volition be a lot less piece of work and mess as yous won't have to drill any large holes through walls, only it does have a downside.

In lodge to go up and over there are in near cases going to exist some quite precipitous bends. This can easily pb to trapped warm air and wet in the pipework which in turn can lead to mould growth in the pipes themselves which is not ideal.

Additionally, venting directly downwards from the soffit can result in the moist air beingness expelled to actually travel back up into the vent or even go trapped under the soffit causing damp and mould growth.

Ideally, venting should exist done in as straight a line as possible so that the resulting exhausted air and fumes are forced away from the building itself.

With the above in listen, if you can exercise this then going through the wall should offer the best results, and then this is the style we are going to go.

Some manufacturers supply a template that tin be placed on the wall and used to marking the position of where you need to drill your vent hole. If not, cheque the manufacturers instructions for the size of hole you need to make. Information technology should either be 120mm or 150mm.

Marker the width of the top of the ducting area on the wall either side and then, using a spirit level, mark a vertical line upwardly, either side of the ducting on the wall using a pencil.

This will mark the width of the tiptop section of duct, and then that you lot can and then find the centre between the 2 lines. Measure out this width and divide past two, to find the centre and then marker this width in two places, top and lesser, between your ducting lines and then use a spirit level or straight edge to join them together making a direct line.

Measure upwards the line, from the top of your ducting section on top the hood somewhere between 400mm and 600mm and make a pencil marker on your direct line. This at present marks the bespeak that you volition demand to bore your vent hole.

The manufacturer may state in their installation instructions what height your vent hole needs to be made at, if so, follow these guidelines. If not the guidelines above should be suitable.

Every bit long equally you have plenty space to run from the top of the duct to the vent hole with some additional ducting using equally smooth a bend equally possible, this should be fine.

With your vent hole position marked, remove the fixings and your hood and duct and put information technology all out of the fashion in a safe place.

Outline of the ducting marked on the wall also as the vent hole position

What are the Primary Vent Options?

When it comes to getting your extracted air through the wall to the exterior earth, you lot practice take a couple of options:

- Rectangular Flat Channel: As you may have guessed, this is flat and rectangular. Quite new and has emerged over the terminal 10 years or so. Designed to be just a flake smaller than a standard domestic brick meaning that a brick tin hands be knocked out of a wall and this size vent or channeling tin replace information technology

Rectangular flat channel ducting

- Circular 100mm Flexible Ducting: This type of ducting is what is traditionally used for about venting jobs. Made of either PVC or aluminium, information technology can easily be extended and shaped so that it can be routed to pretty much any location

100mm flexible pvc duct

- Soil Pipe: This may not exist the obvious selection, but it tin be used as ducting, although due to it'south rigid nature, can exist hard to get into the verbal location you need and also join to other type of duct without the employ of adaptor sockets

In this example we are going to go through the wall. With your cooker hood kit y'all should besides have supplied a through the wall pipe kit. This should consist of an external wall vent, internal adaptor plate and a section of (normally, only can be solid) flexi pipage to run betwixt the two vents through the wall.

In terms of this, you may be thinking; why can't I just vent into the cavity? There are many reasons why this is a really bad idea.

The point of why we are doing this is to remove boiling, moisture-laden air from our kitchen to the outside to preclude any associated clammy and moisture related issues in the kitchen.

If we simply dump this into our cavity, this again will brand the cavity damp, which will seep through to our internal walls causing untold damp problems and damage.

Additionally, the warm moist air tin likewise rise up in our loft space, again, causing damp bug and potentially mould and rot in the many timbers that hold your roof up!

Drilling the Vent Hole Through the Wall

Due to the size of the pigsty that's needed, we are going to use a 110mm diamond core bit.

If yous have never seem i of these before, checkout the image below

110mm diamond core chip to be used with SDS drill

Equally I'k sure you tin can imagine, a bit of this size is going to demand some grunt to go it to cut cleanly through a solid masonry wall.

To power the drill bit we are going to need to employ a large SDS drill of at least 800w. Checkout the link to a higher place to our type of drill and drivers project to find out more virtually big rotary SDS drills.

The chances are that you are non going to own any of this kit so the best pick is to hire information technology from your local hire shop. If yous pop in to your local branch and explain what you are doing they volition get you sorted with the right kit for the job.

Before you start drilling, this is a very messy and dusty job and so remove as much from the expanse your working in as possible and encompass up annihilation that can't exist moved.

With your drill and drill flake at the ready, go yourself in a comfortable position and put the centre drill of your arbour on the marking you fabricated earlier for your vent pigsty.

Commencement drilling slowly and build upwards the speed. Make sure that you hold the drill totally level to forbid the cadre drill binding and jamming while you're drilling.

Using a cadre drill – Image courtesy of youtube.com

While drilling, don't push button on the drill too hard. Let it and the core bit exercise the piece of work. Also, periodically stop drilling to check your piece of work and let the scrap and drill cool down a chip.

When you are virtually xv-20mm from finishing, stop drilling on the within and move to the outside.

The centre pilot drill of your arbour should at present have outburst through the external wall and so you can utilise this point to first once more from the outside and drill towards the within to cease.

You may be asking yourself why you would practise this, why not just drill straight through form the inside?

In reply to this, every bit a drill of this size bursts through when you lot get to the outside wall, the force that this happens at generally takes huge chunks out of the surrounding wall, causing a fair flake of harm.

To forestall this form happening, you drill from the outside in so that you are left with a dainty tidy hole.

If you are using the rectangular channel ducting then y'all are going to need to remove a brick or to. To practise this see our removing and replacing a brick project hither.

Install External Vent and Ducting Through the Wall

With your hole drilled you can now get the external duct fixed in identify. In almost cases, your hood kit should include an external vent, associated pipework and internal duct connection.

If non, y'all will need to get a kit yourself, something similar to the below should exist fine. Just brand sure that the circular connectors on the internal wall plate are the same size as connection point on your cooker hood duct.

Complete through-the-wall cooker hood vent kit

By and large, this should be the case equally they are usually 100mm.

Start by mounting the internal plate on the wall. Do do this, put in in place over the pigsty in the wall and ensure information technology's level using a spirit level.

Marks each of the fixing holes through the hole of the plate on to the wall and then that yous know where to drill.

Put the plate to one side and, using a suitable masonry drill (6mm should be fine), drill out each pigsty, articulate any debris and so insert a wall plug in each.

Earlier actually fixing the plate to the wall you will need to attach the section of pipage (normally flexi pvc) that runs through the wall to the mountain. The fixings to exercise so should exist supplied with the kit, if not, a large zip tie will practise the trick. Just brand sure it's done up tight and that the pipe is securely gripped.

Thread the pipage through the wall to the outside and pop the plate support on the wall and spiral it into place.

At present head exterior and repeat the above for the external plate, but this time you will need to pull the pipe as taught as possible and trim off whatever excess earlier fixing to the external plate.

If the pipage is too slack then it volition affect the efficiency of the extraction process and could cause a buildup of mould.

You won't physically be able to get it taught plenty to pull out all of the folds just get information technology equally stretched as you can.

Get the Power Supply in Place

The final chore earlier actually getting everything fixed in identify is to go a power supply in identify for the hood fan and light.

Substantially this can be done i of two different ways:

- Fused Spur: A spur is taken off of a nearby lighting or socket excursion using a junction box to provide power. If using this method, information technology will need to be proceeded by a fused unit with a 3amp fuse due east.1000. Existing circuit > Junction Box > Fused Spur > Ability to Hood

- Plug and Socket: A new socket can be spurred off of the existing circuit via a junction box and placed within the superlative ducting expanse or loft if the duct runs upwards to the ceiling. A iii-pivot plug is then fixed to the hood, that features a 3amp fuse which is then plugged into the socket

Either of the 2 options higher up should exist fine, so it actually comes down to which is the most convenient, just in most cases, the fused spur pick will probably be the one to become for.

If you accept skillful access within your loft area, then locating a power supply to spur from should not exist an issue.

When it comes to the actual electrical work itself, earlier y'all do any work what so ever, make sure that whatsoever circuits yous are working in are isolated and non alive! More than information on working with electricity safely can be constitute in our electric safety project hither.

In technical terms, what you will be doing is creating a "spur socket". This is a new socket that runs off of an existing circuit.

For a total explanation of how to wire a spur socket, encounter our project page here and also check out our project on radial circuits every bit this also explains the process.

It is important that you lot read the two projects above, as together they run through the right and safe procedure for getting the power supply prepared for your new hood.

1 point to note is that as we are only powering a light and a relatively depression ability fan, we can safely use 1mm or 1.5mm flat cablevision

In the event that you lot do not have a hood that runs all the fashion up to the ceiling, having an unsightly wire flapping around in the empty space may be rather less than desirable.

If this is the instance then it's a good idea to chase the wire into the wall and hide it. As nosotros have already made a mess by chopping a great hole in the wall, now's the platonic time to brand a fiddling more.

This process involves cutting a small-scale channel (most 20mm broad and x-15mm deep) in the wall that the wire will run downwardly. Once the wire is in place, the channel is filled in with a unproblematic filler or cement mix that then hides the wire from sight.

For a full explanation of the rules and steps involved in cutting and filling a chase, meet our project hither.

Set the Hood and Ducting into Place

With the vent pigsty drilled, power in place and fixings all ready, it'due south at present time to get the hood and ducting on the wall.

Give your second pair of easily a shout for some aid again and betwixt y'all, get the hood and duct section up in place on the wall, aligned with your fixing points.

If your particular cooker hood features a hanging subclass setup in terms of the fixings, hang the fixing points of the hood on to the brackets. This will now provide some back up while you lot get the additional fixings secured.

Commencement with those fixings on or nearest the actual hood section and go these secured to provide some back up to the base surface area and and then get whatsoever others secured. Your hood and bottom section of duct should now be fixed securely in place.

Next, connect up your ability wire to the hood in accordance to the manufacturers instructions. Again, before you lot do anything, make sure the power to the circuit your working on is isolated and your new wire is not live!

With the ability continued, plow the circuit on at the point of isolation (at the consumer unit or fuse box) and exam both the fan and the lite to brand sure they both piece of work as expected.

Hood and duct fixed in place on wall

Connect Hood Duct to Internal Vent Plate

We're almost at that place now, non much left to do.

One of the last jobs is to connect the summit of the hood duct to the inner vent plate.

Both should feature a 100mm (iv inch) round aperture that is designed to take 100mm PVC or aluminium ducting. If you tin can, get for the PVC blazon equally this is a little less prone to tearing than the aluminium, plus the aluminium tends to create an echo effect inside the pipage when the fan is running, creating unnecessary noise.

As we did above, secure one end of the duct to the peak of the hood using cable ties and run the residuum of the pipe upward to the connection on the inner wall plate.

As earlier, get the pipage as taught as possible, removing as many creases as possible and then secure it to the inner wall plate.

Before moving on to our terminal task, just bank check the joins to make certain they are secure and do not motion.

Get the Top Duct Cover in Identify

Depending on who manufactured your detail hood will depend on how the top cover is mounted.

You should have the brackets or fixings already in place from the steps to a higher place, only if not, now is the fourth dimension to get them on the wall. Refer to the manufacturer instructions for how this should be done if they are unique to the hood itself.

Your centre lines should already exist in identify on the wall so utilise these to find whatsoever centre points.

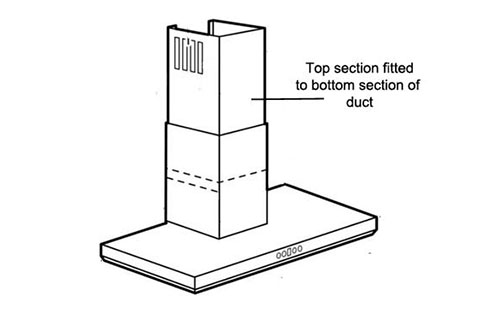

In nearly cases the top cover section of your cooker hood should slip over the bottom section with a bit of an overlap. This is to permit yous a petty height adjustment to compensate for the many differing ceiling heights.

With some systems, the acme section volition in fact slide down inside the bottom section, this is something to be aware of. Check your instructions for exactly how information technology should fit together.

When getting the encompass in place, but exist careful non to slide it up and downwards the bottom section as this can cause scratches and marks and if information technology's stainless steel, you'll never become these out.

With the embrace in place, make certain information technology'due south sitting on any brackets or mounts correctly and then secure it to the wall.

Summit section of cooker hood fitted in place

You lot should now be pretty much done. Just run the fan on all the different settings or speeds to brand sure information technology'due south working as it should and finally test the light once again.

Installing a cooker hood and ventilation ducting is a relatively straight frontward job as long as you accept your time and plan everything out.

As we accept mentioned, ensure you stay prophylactic at all times when working with electricity, run across our projection above for more help and communication.

Source: https://www.diydoctor.org.uk/projects/ventilation-ducting.htm

Posted by: ellisaffel1999.blogspot.com

0 Response to "How To Install Cooker Hood Extractor"

Post a Comment